Building Systems

Building Systems

Proven and reliable engineering

Morris Group’s proven and reliable engineering has been the driving force from every beginning. With the emphasis on customer service and quality craftsmanship, our company’s primary focus is on client satisfaction. Our mission is to leverage decades of benchmark engineering & exceptional service to design, manufacture & deliver the best fabric structures in the industry.

We offer high-quality solutions that are custom designed to account for location-specific needs. With decades of experience, we pride ourselves on being able to deliver whatever our clients require, whether it be a standard structure or a full turnkey fabric building. We strive to provide our customers with the comfort they need to safely store and protect their assets.

Customizable & Expandable

Usage

• Sand & Salt storage

• Fertilizer storage

• Agricultural usage (ex. Dairy facility, Hay storage, etc.)

• Commercial usage (Manufacturing facility)

• Equipment storage

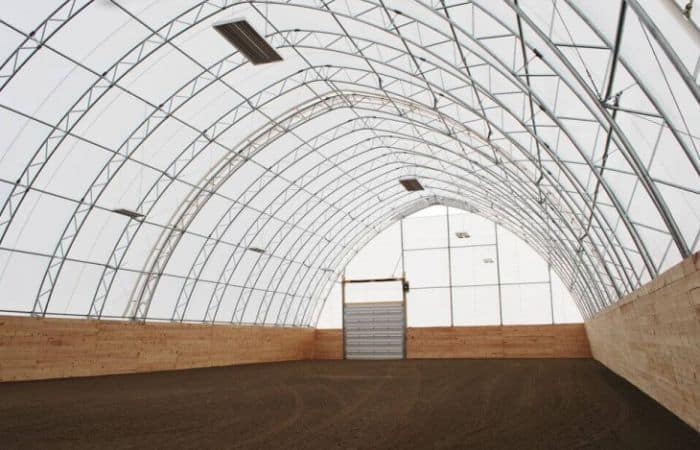

• Equine riding facility

• Recreational facility

• Multi-use and/or Portable

Size

• Widths for most engineered structures can start at 30’ and go up to 200’ or more

• Leg height can go up to 14’ or more on customizable buildings increasing overall height

End Walls

• Fabric

• Steel

• Wood

• Various door sizes and locations

Foundation

• Concrete

• Steel i-beam

• Wood post

• Helical anchors

• Sea containers

Fabric Cover Options

• HDPE (High Density Polyethylene)

• Lined and insulated

• PVC

• Bag style cover or Keder system (used for long or large-s size buildings)

• Skylights

• Colour options vary, but lighter colours offer natural light to reduce electricity costs

• Flame-retardant fabrics available

What structure can we build for you?

CC Series

Utilty Storage

Widths Available: 32′, 42′, 52′ & 62′

This ideal adapatable building design allows you to achieve greater capacity for any budget.

HT Series

High Top

Widths Available: 50″, 60′, 65′, 72′ & 82′

High Top has extra interior height with “tank” toughness for heavy snow load areas.

VP Series

Custom Design

Widths Available: From 30′ to 200′

Distinctive and traditional buildings ranging from any size, for any type of application, anywhere in the world.

CL Series

Container Lined

Widths Available: 32′, 36′, 40′ & 50′

The FIRST-EVER frabric building in the industry designed and engineered exclusively for container use.

Related projects

View the latest project

Morris Group has worked with many clients and companies over the years to create cost-effective turn-key solutions. If you’re interested in our Building Systems solutions, view one of our recent projects to learn more.

Frequently asked questions

How can I be sure that Morris Group are the right people for the job?

You can rest assured that our team will mow over every detail to make sure that your structure will not only have an optimal design and appearance, but will also last longer. Our customers say it for us with their repeat business and their referrals.

What kind of experience does Morris Group have?

We have over twenty years in the fabric and steel building industry.

What guarantees do you offer that the job will be finished on time and on budget?

Nobody can guarantee this. The construction industry is heavily dependent on the weather. What we can guarantee is that keeping our customer on schedule is part of the reason we are successful.

Why Hot Dip Galvanized Frame?

The Hot Dip galvanizing process means that structures last longer. Studies show that next to stainless steel, hot dip galvanizing (HDG) is the best protection against rust and weathering. The hot dip galvanizing process makes trusses strong and more reliable, while creating a smooth surface that won’t snag or tear the cover. Look for galvanizing according to longestablished, well accepted and approved standards such as ASTM-123, CSA G164 the Canadian Standards Association (CSA), and the American Association of State Highway and Transportation Officials (AASHTO). These standards cover everything from minimum required coating thickness for various categories of galvanized items to the composition of the zinc metal used in the process. One important note is that “In-Line Galvanized steel” is NOT galvanized on the inside. The tube is coated on the inside with a thin layer of Inorganic Zinc-Rich Paint which reduces the service life and durability significantly and may not meet required minimums due to applicator skill. Given this important factor, the key question to ask about hot dip galvanizing is whether their welded trusses are hot dipped after manufacturing.